Carburization Damage in Heater Tubes

- Home

- Damage Specific Solutions

- Carburization Damage in Heater Tubes

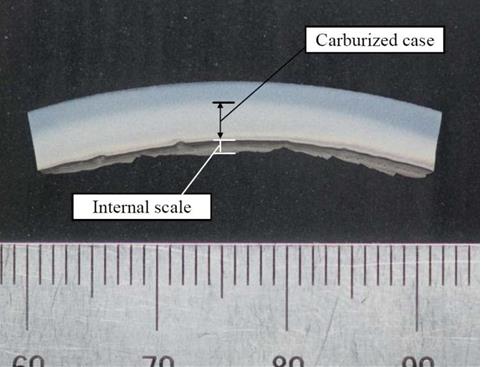

Furnace tubes that are made of high chrome material often will carburize when in hydrocarbon service.

Coker furnaces, found in oil refineries are particularly susceptible to carburization which starts on the inside of the tube. As the material carburizes, it loses ductility and can eventually fail. The carburized material represents virtually no actual wall loss, therefore A-Scan ultrasonics is ineffective at determining caburized thickness.

At Focus Integrity Solutions we have all the required expertises along with needed equipment to differentiate and distinguish between the different stages of damages. This helps our clients to take decision on repair and replacement of the carburized tubes.