Pulsed Eddy Current for CUI

Corrosion under insulation and fireproofing occurs as a result of moisture penetration and warm temperatures in pipework, vessels and other insulated assets. It often takes the form of general corrosion. CUI and CUF are difficult to detect as they are hidden by the protective layers and likely only found when insulation or fireproofing is removed for visual inspection or when a leak occurs, unless an advanced non-destructive testing (NDT) method such as Pulsed Eddy Current is used.

In pulsed eddy current (PEC) inspection, a probe induces eddy currents in a component, and the probe measures wall thickness by tracking the amount of time it takes the eddy currents to decay. The thicker the wall, the longer it takes for the eddy currents to decay to zero. PEC can be applied to in-service assets, and can detect damages through insulation and fireproofing, so it is an effective tool for corrosion-under-insulation (CUI) assessments.

Application

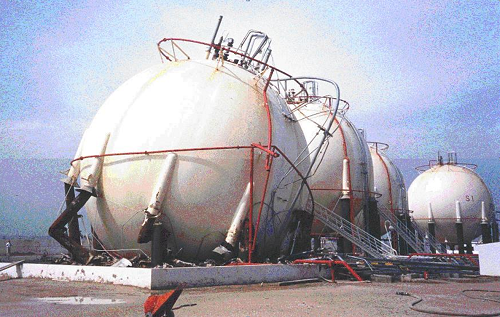

- Insulated in-service Tanks, Piping & Vessels.

- Sphere Legs

- Insulated Cryogenic Tanks and Piping

- Tank Floors with Fiberglass Coatings

- Offshore Platform Legs

- Fireproofed Structural Beams.

- Refractory lined vessels

- Offshore Platform Legs

- Ship Hulls

Capability

- Performed in service during plant operation

- Provides the average remaining wall thickness measurement within the probe foot print.

- Direct contact is not required and wall thickness can be measured through any non-conductive material up to 200 mm thick, e.g. insulation material (Stainless Steel and Aluminum sheeting less than or equal to 1mm), paint, bitumen, dirt etc.

- Surface preparation is not required enabling measurements to be taken through corrosion products.

- Wide temperature range -100°C to 550°C.

- Battery operated and robust design suitable for Rope Access and splash zone inspection deployment. Fast and reliable data collection typically 700 to 1000 readings per day.