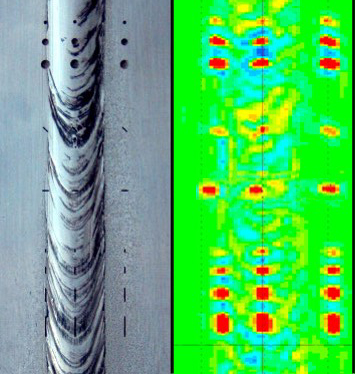

Surface Inspection by Eddy Current Array Technique

- Home

- Electromagnetic Testing Solutions

- Surface Inspection by Eddy Current Array Technique

The eddy current array technique (ECA) is a derivative of conventional eddy current testing and shares the same electromagnetic/inductive principles of eddy current.

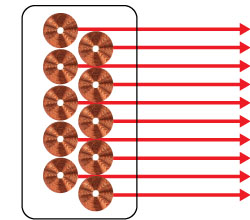

The word “array” means that in comparison to a single coil sensor many adjoining eddy current coils are forming a coherent eddy current assembly. The decisive advantage of Eddy Current Array Technique (ECA) ECA probes is their larger coverage compared to single coil probes and thus a faster and more cost efficient scanning for the client.

Focus Integrity Solutions Private Limited provides quality inspections, with real-time results, Our quick response is available for all below mentioned applications within and outside India.