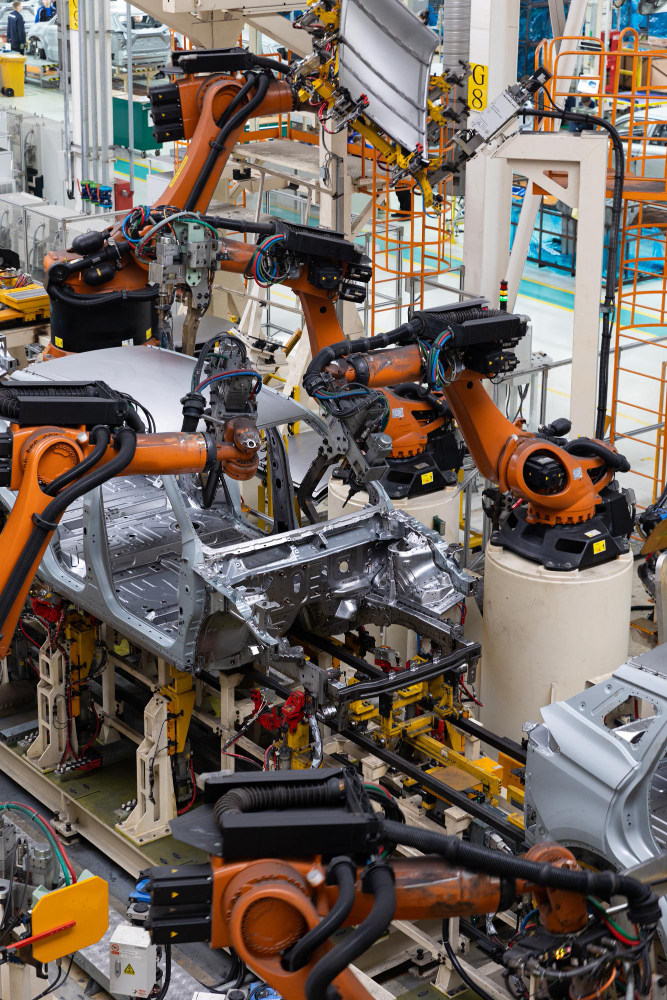

Manufacturing

In the fast-paced manufacturing industry, maintaining the integrity and performance of your equipment is crucial to ensuring product quality, operational efficiency, and safety. At Focus Integrity Solutions, we provide advanced inspection and asset protection services designed to help manufacturers extend the lifespan of machinery, reduce downtime, and prevent costly failures. Whether you’re producing heavy machinery, automotive parts, or precision components, our non-destructive testing (NDT) methods offer comprehensive solutions to keep your operations running smoothly.

Our Expertise in Manufacturing

With years of experience serving the manufacturing sector, we understand the critical need for accurate, real-time inspections to prevent failures and optimize production. Our services are designed to meet the demanding requirements of diverse manufacturing environments, including heavy machinery, automotive, aerospace, and precision engineering.

Key Services We Provide

- Weld Integrity and Quality Assurance

- Technologies Used: Phased Array Ultrasonic Testing (PAUT), Time-Of-Flight Diffraction (TOFD), Eddy Current Array (ECA)

- Outcome: We conduct detailed inspections of welded joints in machinery, structural components, and pressure vessels to detect cracks, porosity, and other defects that could compromise strength and safety.

- Component and Machinery Inspection

- Technologies Used: Conventional Ultrasonic Testing (UT), Eddy Current Testing (ECT), Magnetic Particle Testing (MPT)

- Outcome: Our services ensure that critical components such as shafts, gears, and machine housings are free from surface and subsurface defects, extending their operational life and preventing sudden failures during production.

- Casting and Forging Inspections

- Technologies Used: Radiographic Testing (RT), Ultrasonic Testing (UT), Magnetic Flux Leakage (MFL)

- Outcome: We provide in-depth inspections of cast and forged parts, detecting internal voids, cracks, and other potential issues that could affect the integrity of large structural components or machinery.

- Fatigue and Stress Crack Detection

- Technologies Used: Phased Array Ultrasonic Testing (PAUT), Time-Of-Flight Diffraction (TOFD), Visual and Dye Penetrant Testing (PT)

- Outcome: Our specialized inspection techniques help detect fatigue cracks and stress-induced damage in critical machinery parts, preventing operational failures and enhancing overall equipment reliability.

- Non-Destructive Testing for Metal Alloys

- Technologies Used: Eddy Current Array (ECA), Magnetic Particle Testing (MPT), Ultrasonic Testing (UT)

- Outcome: We provide accurate inspection and assessment of various metal alloys used in manufacturing, ensuring that materials are free from defects like cracks, corrosion, and porosity that could affect product quality.

- Corrosion and Erosion Detection

- Technologies Used: Ultrasonic Thickness Measurement, Eddy Current Testing (ECT), Pulse Eddy Current (PEC)

- Outcome: We help detect internal and external corrosion or erosion in machinery, pipes, and other components, preventing leaks, structural failures, and unsafe working conditions.

- Product and Equipment Compliance

- Technologies Used: Visual Inspection, Ultrasonic Testing (UT), Radiographic Testing (RT)

- Outcome: We ensure that products and equipment meet industry standards and regulatory requirements through comprehensive compliance testing, avoiding costly regulatory violations and product recalls.

Why Choose Focus Integrity Solutions for Manufacturing Assets?

- Tailored Solutions: We understand the unique challenges in manufacturing environments, and offer customized NDT solutions to meet your specific production needs.

- State-of-the-Art Technology: We utilize the latest inspection technologies to provide fast, accurate, and non-invasive inspections that minimize downtime and prevent disruptions in your production process.

- Enhanced Safety: Our inspections help identify potential issues before they lead to failures, ensuring that your equipment operates safely and meets all safety regulations.

- Cost-Effective: Early detection of flaws helps you avoid expensive repairs, reduce the risk of unexpected equipment failure, and improve the overall operational efficiency of your manufacturing facility.

- Global Expertise: With experience serving manufacturers worldwide, we are equipped to provide services in both large-scale and small-scale manufacturing environments.

Our Impact in Manufacturing

At Focus Integrity Solutions, we are dedicated to improving the efficiency, safety, and reliability of your manufacturing processes. Our NDT services help reduce operational risks, extend the life of critical equipment, and maintain the quality of your products. Whether you’re producing large industrial machines or precision components, we provide the inspections needed to keep your operations running smoothly and cost-effectively.